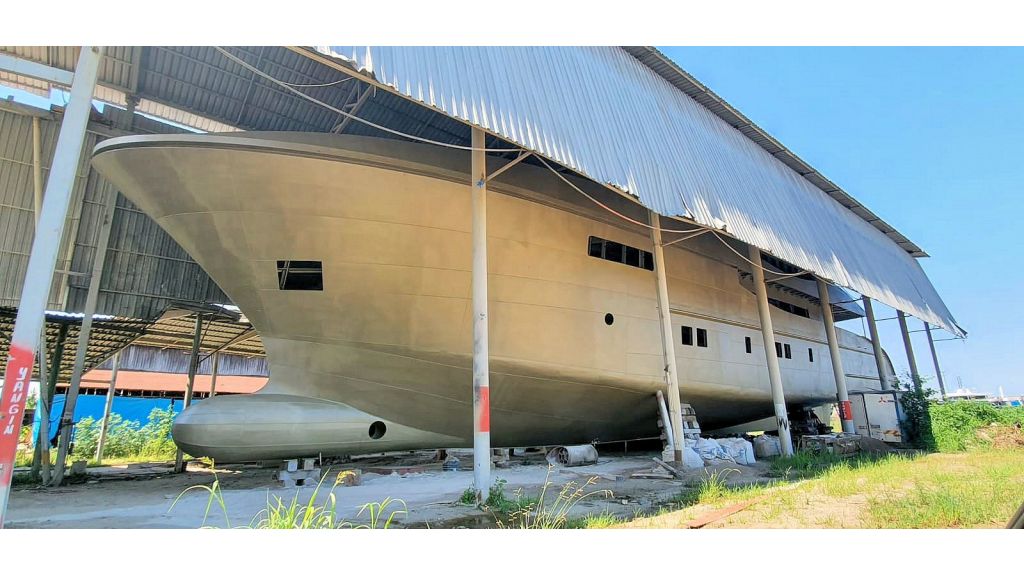

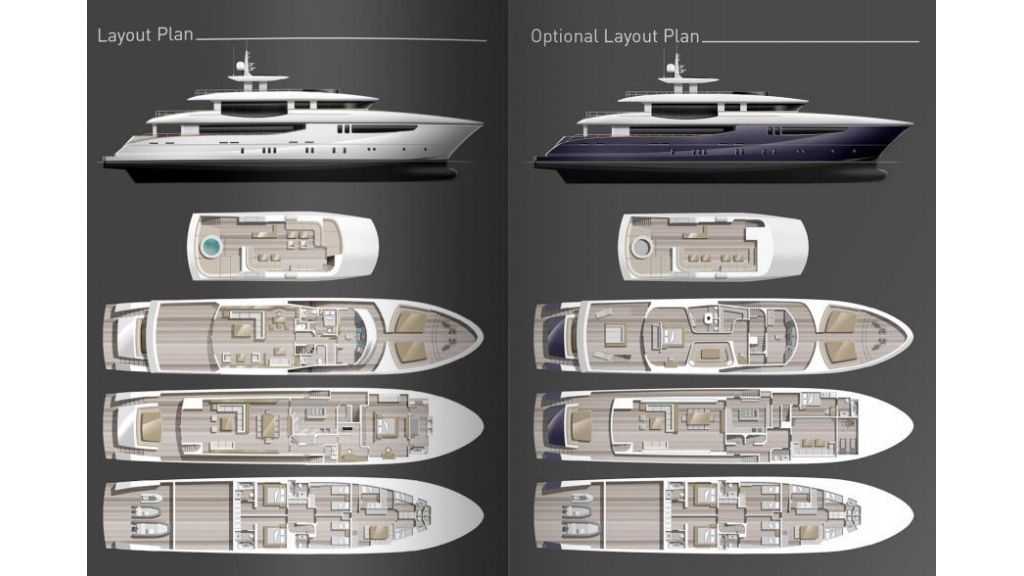

Steel Hull Motor Yacht

43m Steel hull motor yacht is currently abandoned project

She will be under construction for another 18 months.

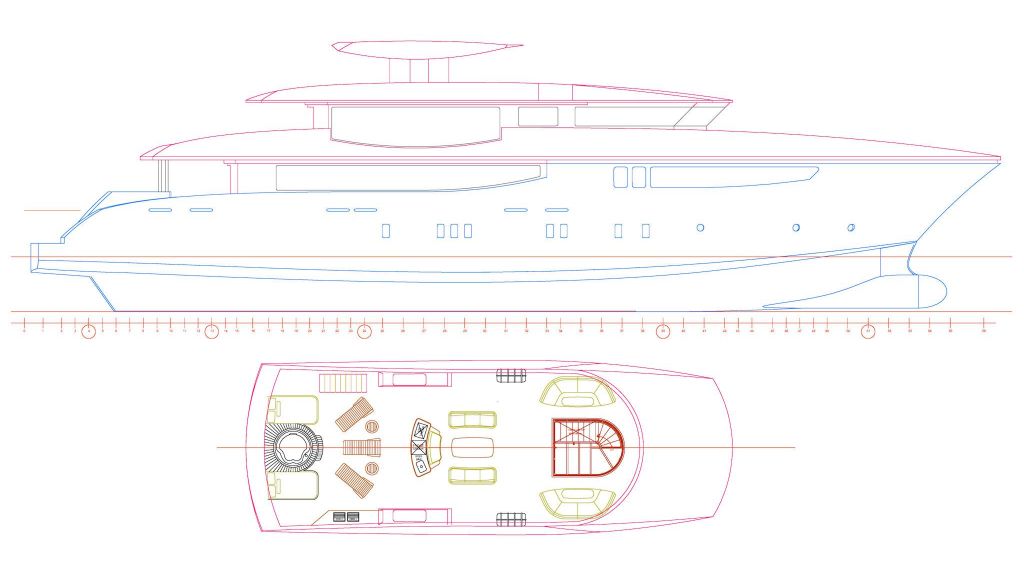

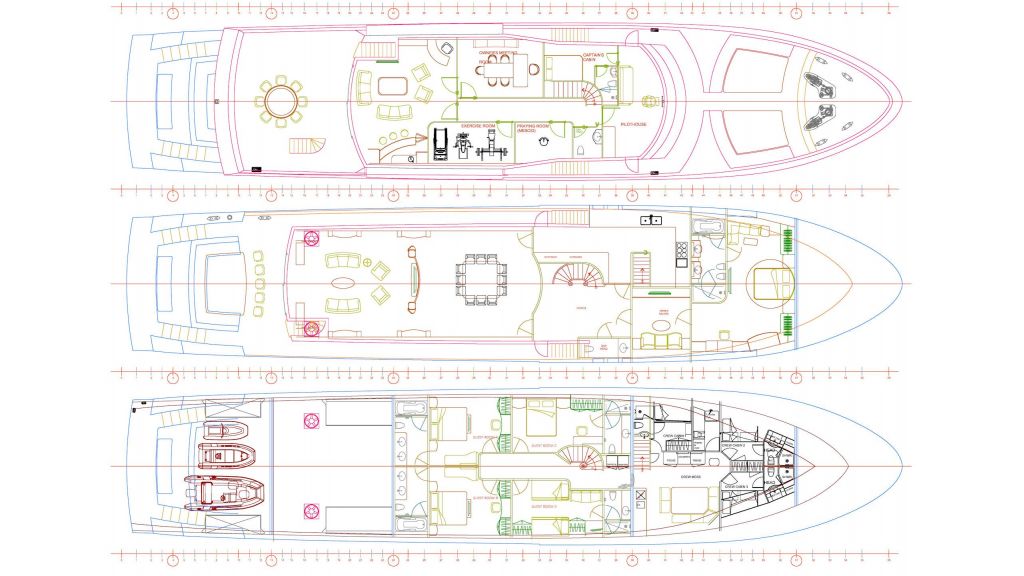

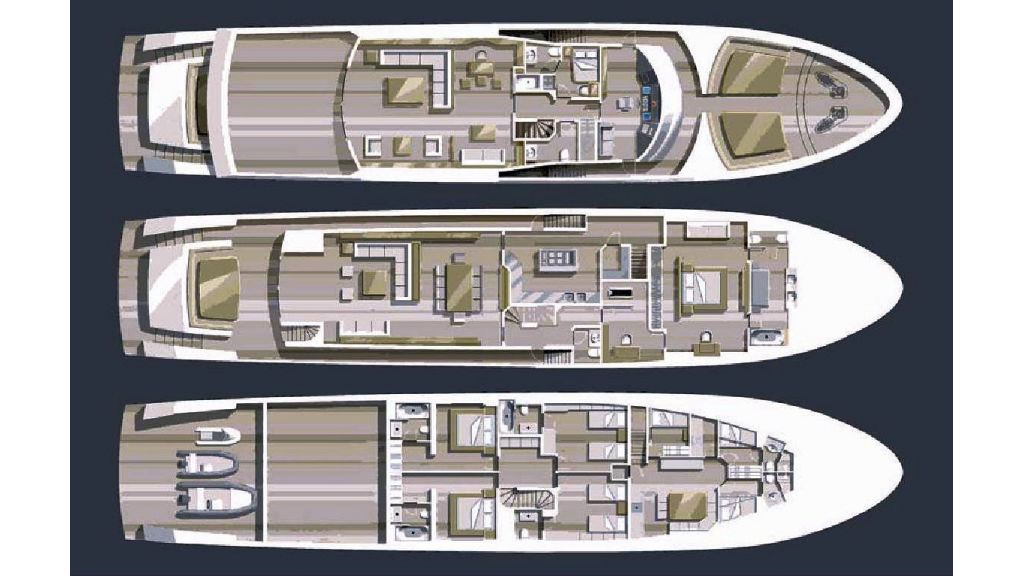

The design of motor yacht 42.5 m has been done by a certain experienced in-house team of the shipyard. From the preliminary design stage to the current condition, each step has been achieved by computer aided design and production methods. (CAD + CAM). Therefore, the 3D design advantages have also been added to the production at any stage.

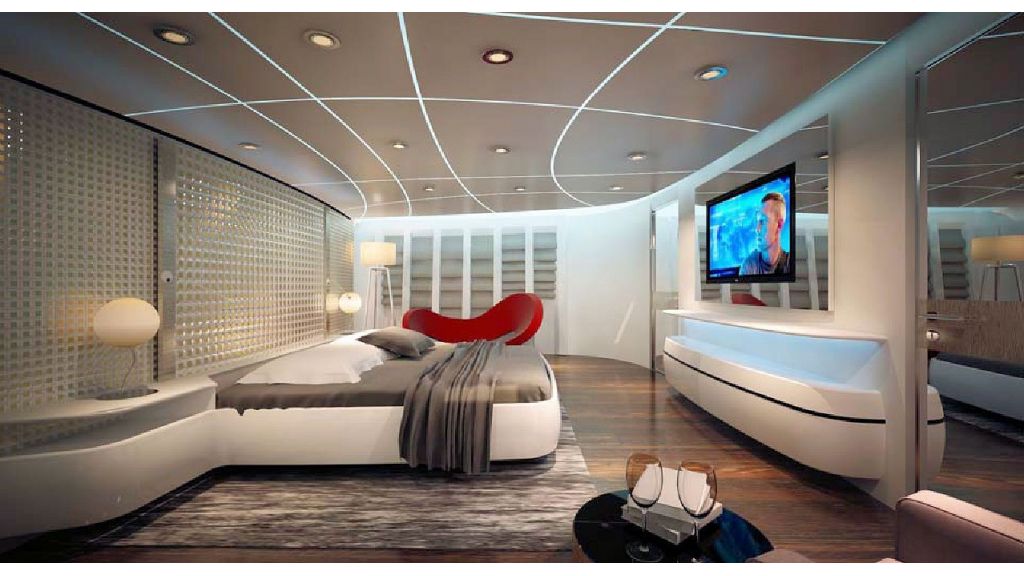

In the beginning, during the design preparation stage, the main request of the Owner was to have a sleek & modern viewed boat with a large & fresh interior. Therefore the length was kept as 42.5 m (140’) to be able to provide a boat, big enough to sail on the open seas & oceans and compact enough to anchor at the small bays of the Mediterranean. After many different alternative preparations, at last, the current profile of the boat appeared. This final profile was pretty successful with its sleek and contemporary look. Therefore, to fulfill the fresh interior request;

size of the salons & cabins kept very big and bright, within illusion of really wide windows.

Current Status of Design:

– The construction drawings/details of the boat have been completed. There is no construction situation for main structure of hull & superstructure at the moment. All required structural drawings were sent and approved by RINA.

– The design definitions of;

— General Arrangement Plan & General Particulars

— Tank Plan and Capacity

— Principal Engine Room Layout (Preliminary; depending on the engine park equipment decisions)

— Principal Main Engine & Propulsion System Layout Plans (Preliminary; depending on the main engine brand and propulsion system manufacturer decisions)

— Anchoring System Details and Windlass Layout

— Porthole Layout & Construction Plan

— Schematics of Bilge & Fire, Sea Water, Fuel, Fresh Water Systems (Preliminary; depending on the engine room equipment plan)

The boat has been classed at the rules of RINA (Registro Italiano Navale) with the notation of “C, +HULL, oMACH, Y Private Yacht”. Design and production control of the boat has been done by RINA

Current Status of RINA:

– Construction drawings were already sent to RINA for their further control and approval before production was started. All sent drawings approved with very minor remarks and notes on.

– Regarding RINA surveyor’s requests; before starting the production, all steel plates and pipes were mechanically and chemically tested for quality (A grade) and strength control. Each and every test was found adequate.

– The welders of the shipyard were also examined by RINA to ensure the welding quality level. The welders made welding test pieces under surveyor’s observation.

Regarding the successful results of the welding pieces, the welders are certified by RINA.

During the production, these certified welders were in charge on board.

– During the production, RINA surveyor has made planned and random surveys to control the production. In spite some requests and minor revision advices, all the surveys were found satisfactory.

Note: In case of request, all mentioned stages could be testified by the RINA surveyors in a meeting with some reports as well.

Concerning the completion and delivery of the steel hull & superstructure, a final survey of RINA is needed. The surveyor would check out all their notes from the beginning and control the final status of the construction. This survey might take one or two days work together with RINA surveyor and us.

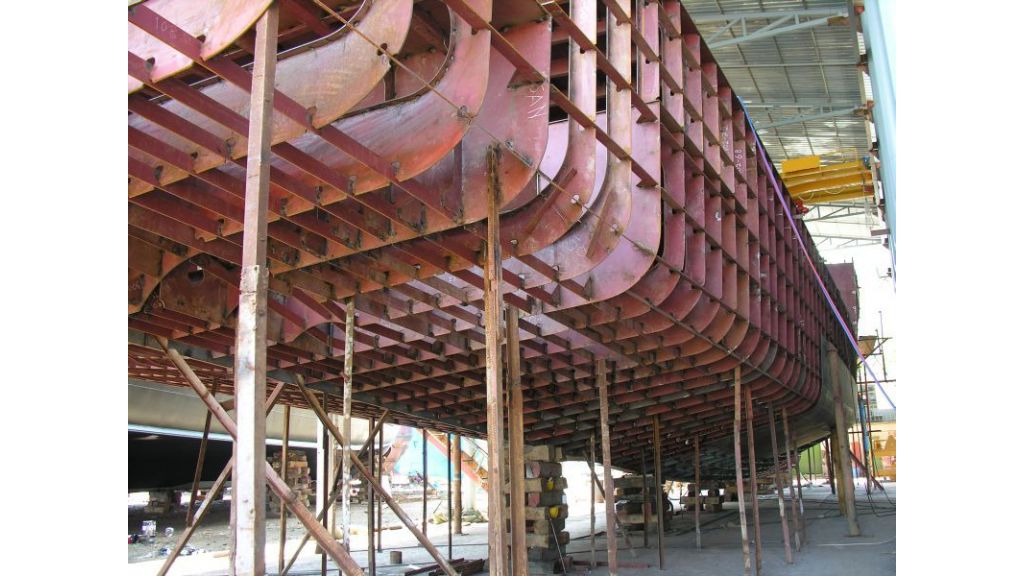

The production of the yacht has been done by very experienced team to reach the highest yacht finishing standards.

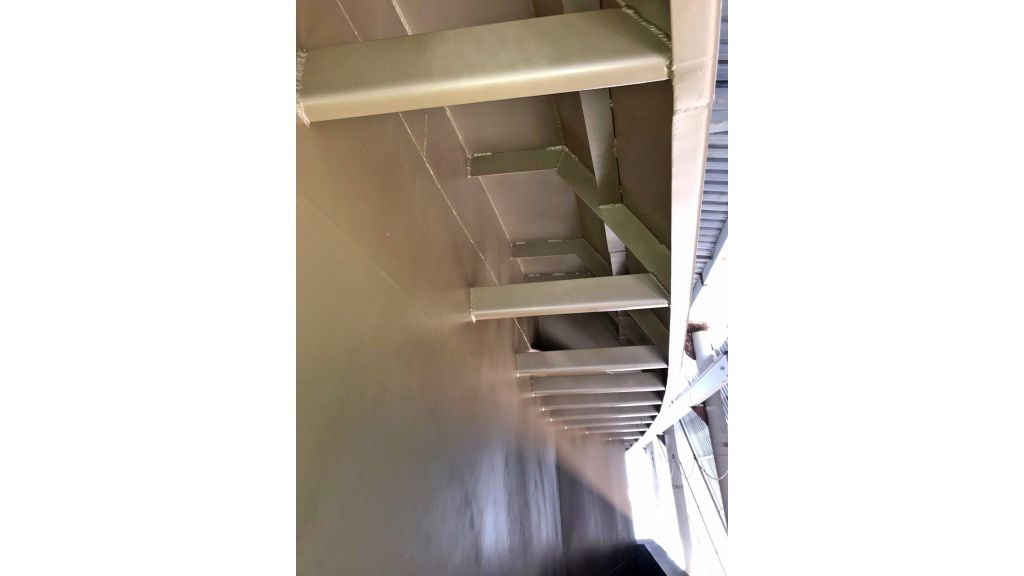

The structural members (including webs, stiffeners, flat bars, brackets, etc.) were prepared at the design office as nesting plans. Regarding these plans, the steel plates cut by the CNC machine with very minor error tolerances. After cut outs of these members, the related team

started to install them as a pre-fabricated product. Afterwards, each product was sent for building of main blocks (as hull and/or superstructure blocks) of the boat. Finally, the structure team (both installation and welding team) erected all the blocks and completed the

structural production of the yacht. As a critical path, during the erection stage, the certified welders have followed the ‘welding sequence’ rules strictly to avoid deformation from the hull & superstructure surfaces. Ultimately, on our boat, these surfaces have been well faired;

so we have managed to reduce the duration & cost of cosmetic paint finishing (filler application & painting).

Quality Control (QC) team has checked each and every step of production starting from the prefabrication stage until the block erection. Within RINA’s contribution and our QC team’s involvement, the production of the boat has been accomplished pretty well until now in good

standards.

Current Status of Production:

– The structure of;

— Hull double bottoms,

— Deep and regular frames’ construction,

— Constructional tanks and their structures,

— Watertight bulkheads and Collision bulkheads,

— Pillar constructions,

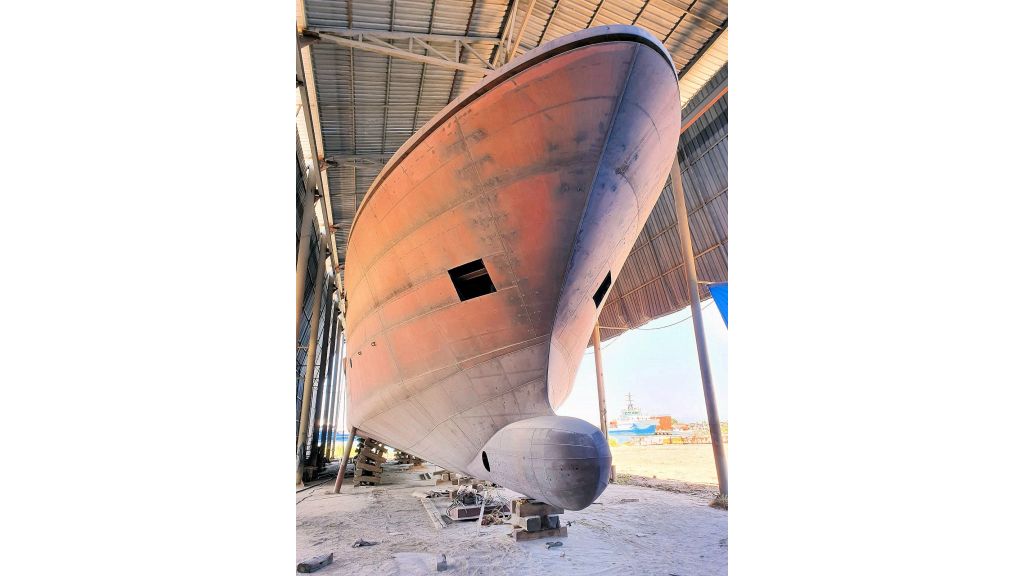

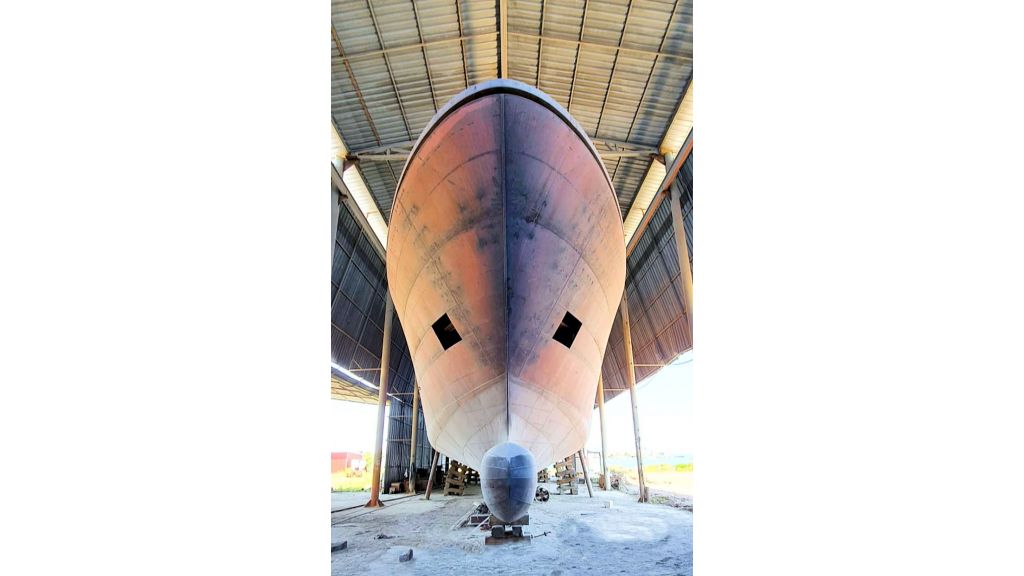

— Bulb construction,

— Bulwark construction,

— Construction of aft steering compartment and swimming platform

— Construction of Deck panels (incl. the lower deck, main deck, upper deck and sun deck panels)

— Construction of Superstructure deck houses (incl. deck house on the main deck and upper deck) have been completed.

– Briefly, the construction of the steel hull & superstructure has been completed. At the next visit of RINA, these completed parts to be delivered to RINA within one or two days of the survey.

– The piping and outfitting works are about to start, up on the final systems & equipment decisions.

Hull Type: Twin propeller displacement motor yacht, round bilge type

Naval Architect: Inhouse Design

Exterior Designer: Inhouse Design

Interior Designer: Inhouse Design

Classification: RINA C, +HULL, oMACH, Y Private Yacht

Material of Hull & S.Structure: Carbon Steel

Length Over All (LOA): 42.55 m 140.00 ft

Beam Moulded (B): 8.30 m 27.20 ft

Draft (T): 2.50 m 8.20 ft

Displacement (50% load): 350 t 771.605 lbs

Maximum Speed (50% Load): 16 knots

Cruising Speed (50% Load): 13 knots

Range at 12 knots: 3.500 N.m.

Fuel Capacity: 60 m3 15,850 US Gallon

Fresh Water Capacity: 11 m3 2,900 US Gallon

Main Engines: CAT, MAN, or MTU

Maximum Power 2 x 1450 HP (1067 kW)

Gear Box: 2 x ZF or Twin Disc

Engine Control: Kobelt, Rexroth or Equal

Water-lubricated Shafts: Stainless Steel Alloy, Ø110 mm

Propellers: Custom, NiBrAl five blade fixed pitch, Ø1400 mm

Generators: 2 x 80 kW, ONAN, Northern Lights or Equal

Emergency Generator: 1 x 33 kW

Bowthruster: Hydraulically Driven, 75 – 100 HP (54 – 74 kW)

Steering System: DATA or Equal

Rudders: Two stainless steel rudder blades with stainless steel boss

Stabilizers: 2 x Fin stabilizer system, Wesmar, TRAC or Equal

Electrical System: 240/380 V AC, 50 Hz, 3 Phase + 24/12 V DC

Shore Supply: 2 x 120 A

Fresh Water Maker: 2 x Idromar or Equal, Total capacity 10,000 lt/day

Hot Water Boiler: 2 x Gianneschi or Equal, Total capacity 300 lt

Sanitary Treatment: Hamann or Equal

Grey / Black Water System: EVAC, JETS, or Equal

Fuel Separator: Alfa-Laval or Equal, Capacity 760 lt/h

Air Conditioner & Fresh Air Sup.: Webasto / Marine Air or Equal,

360.000 BTU (Incl. Fresh Air Supply Unit)

Anchor Capstan: 2 x DATA or Equal, Capacity 5000 kg

Anchor: 2× HHP Pool –Total Weight 315 kg

Anchor Chain: 2 x 137.5 m Stud link – Ø16 mm

Capstans: 2 x DATA or Equal, Capacity 1800 kg

Passerelle: Custom-made, Stainless Steel & Teak

Tenders and sports equipment are Owner’s delivery. The design criteria for tenders and jet-ski’s are foreseen as follows:

Tender: The tender launching arrangement and capacity in the tender garage shall be designed for:

1 x 5.80 m + 1 x 3.20 m, Jet drive, Diesel

1× Yamaha / Sea Doo or Equal, Jet Ski