Tatiana

TATIANA – 80 Meter Bilgin Yachts Superyacht | Ultra Luxury Mega Yacht for Sale

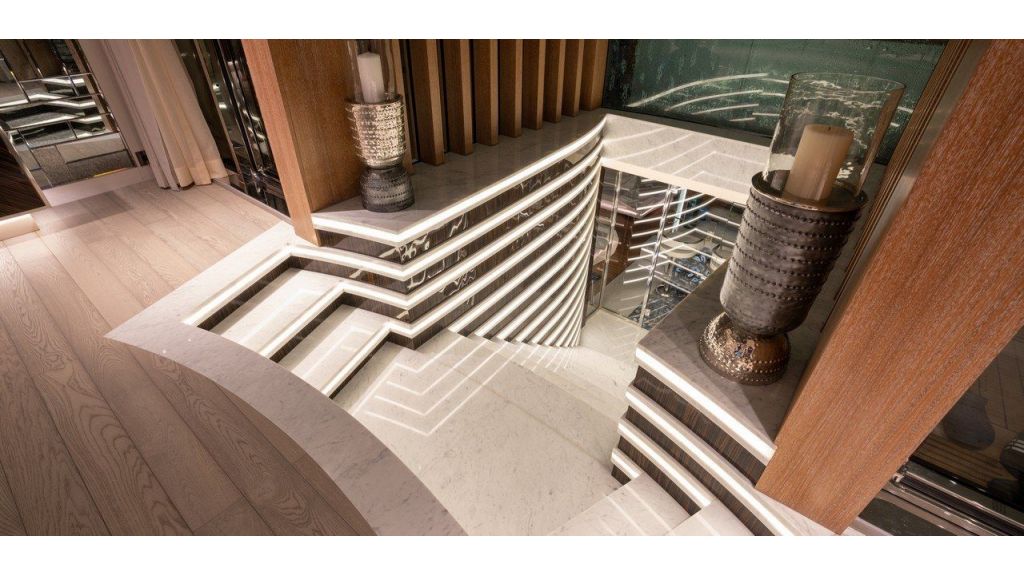

Overview and Design Philosophy

Built in 2021 by Bilgin Yachts, the 80-meter TATIANA is one of the most striking models of the Bilgin 263 series and stands as a benchmark in the global superyacht market. Featuring a steel hull, a 12.2-meter beam, and a maximum draft of 3.50 meters, she delivers both exceptional ocean-going capability and long-range cruising performance. Based in Istanbul and flying the Turkish flag, TATIANA represents the pinnacle of modern mega yacht engineering and design.

With an approximate fully loaded displacement of 1,325 tonnes, this superyacht offers a remarkable range of 5,000 nautical miles at economical cruising speed at half-load displacement, operating on two engines and one generator. Her maximum speed of 19 knots ensures dynamic performance while maintaining refined onboard comfort.

Classification and International Compliance

Classification and International Compliance

TATIANA has been built under the survey of the American Bureau of Shipping (ABS) in full compliance with the Regulations for the Classification of Yachts. Her class notation includes A1, Commercial Yachting Service, AMS, ACCU, RW, (E), COMF +(Y), highlighting her structural integrity, safety, and enhanced comfort standards.

She fully complies with the LY3 – Large Commercial Yacht Code for vessels over 24 meters in load line length and is certified for commercial use carrying up to 12 passengers. The yacht adheres to all relevant COLREG and IMO regulations, and upon completion, MARPOL pollution and sewage certification has been delivered, ensuring environmental compliance and operational excellence.

Machinery and Technical Performance

Powered by 2 x MTU 16V 4000 M73 main engines, TATIANA delivers robust propulsion performance suitable for long ocean crossings and high-speed cruising. Her electrical power system includes 3 x 210 kW and 1 x 150 kW G&M Tex generators (400V), ensuring reliable onboard energy management.

With a fuel capacity of 168,000 liters and a fresh water capacity of 48,000 liters, she is engineered for extended voyages. Additionally, two watermakers provide a combined production capacity of 40,000 liters per day, granting significant autonomy during long-distance cruising.

Hydraulic and Stabilization Systems

The main hydraulic power pack is dedicated to operating the stabilizers and is driven by two 30 HP, 400 VAC, 3-phase electric motors. This ensures maximum comfort both underway and at anchor. The hydraulic systems also support the garage tender crane, jetski deck crane, beach club doors, transom systems, rescue boat deck doors, side boarding ladder, and gangway systems.

Such a comprehensive hydraulic infrastructure reflects the advanced engineering standards expected in an 80-meter mega yacht.

Climate Control and Comfort Systems

The air conditioning system features five CruiseAir scroll-type compressor units with a total cooling capacity of 1,260,000 BTU. Operating on 400 VAC, 3-phase power, the chilled water system supplies tempered water to individual cabin evaporators, ensuring balanced climate control throughout the yacht.

Two fresh air makers distribute dry, pre-cooled fresh air across all interior spaces. The yacht is equipped with 24 JETS vacuum toilets with freshwater flushing and a sewage treatment plant located in the engine room. Four 250-liter, 15 kW DIKO duplex steel hot water boilers connected in series ensure consistent hot water supply across all guest and crew areas.

Deck Equipment and Mooring Systems

Deck Equipment and Mooring Systems

TATIANA is equipped with two electrical vertical windlasses (Hidromarin or equivalent) with 7,000 kg pulling capacity. She features two 970 kg galvanized steel Pool-TW high holding power anchors and two 192.5-meter, 26 mm galvanized stud-link chains. Polished 316L stainless steel chain compressors and hydraulic vertical capstans enhance both operational efficiency and aesthetic refinement.

Safety and Environmental Systems

An automatic Ultrafog water-mist fire extinguishing system protects the entire accommodation area. A MARPOL-compliant RWO oily water separator is installed in accordance with MCA and international maritime regulations. Two 4 kW Azcue Bombas centrifugal pumps operate the bilge and fire systems.

Three screw-type air compressors operating at 10 bar support general service and SCR urea dosing systems, ensuring advanced operational functionality.

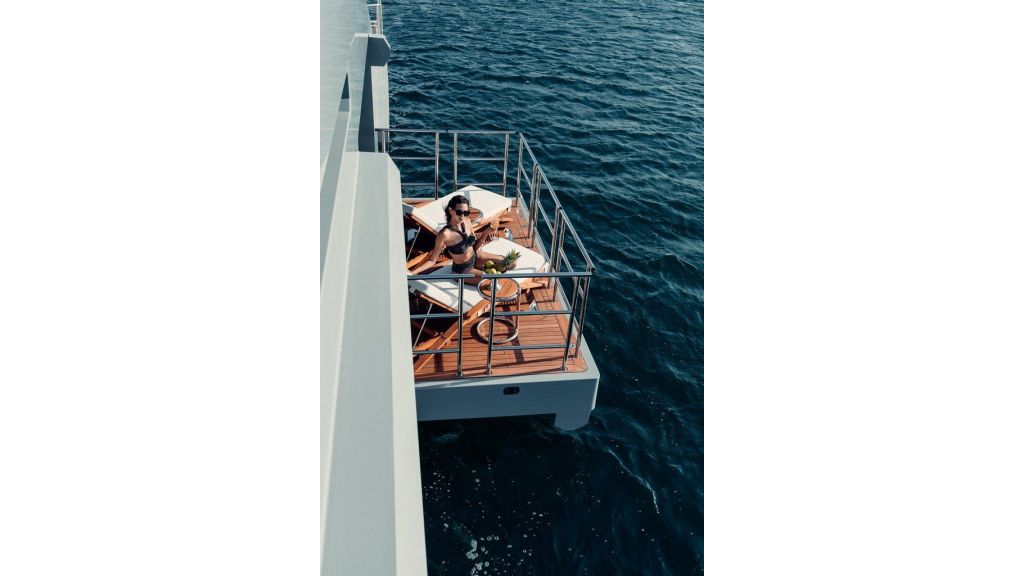

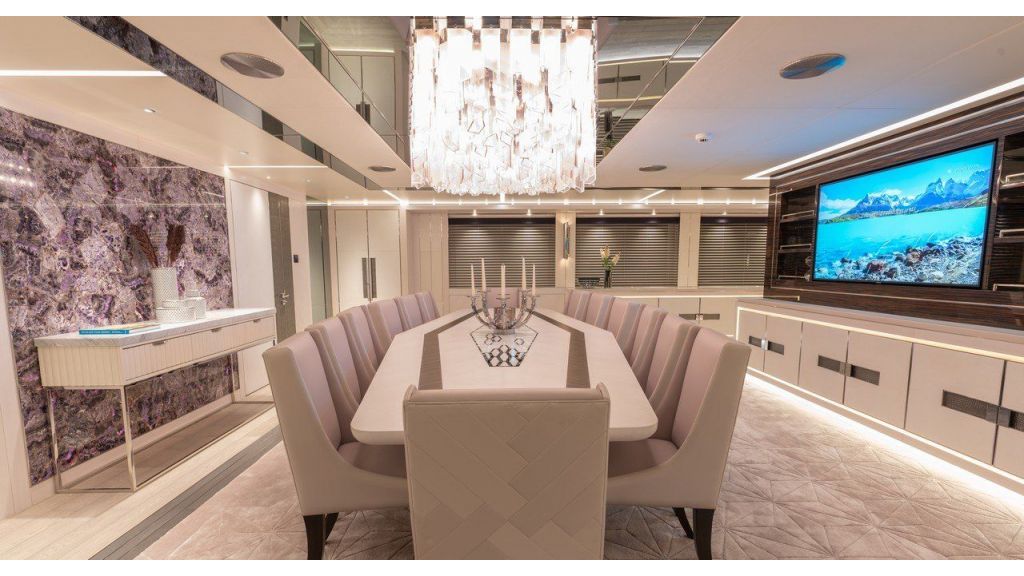

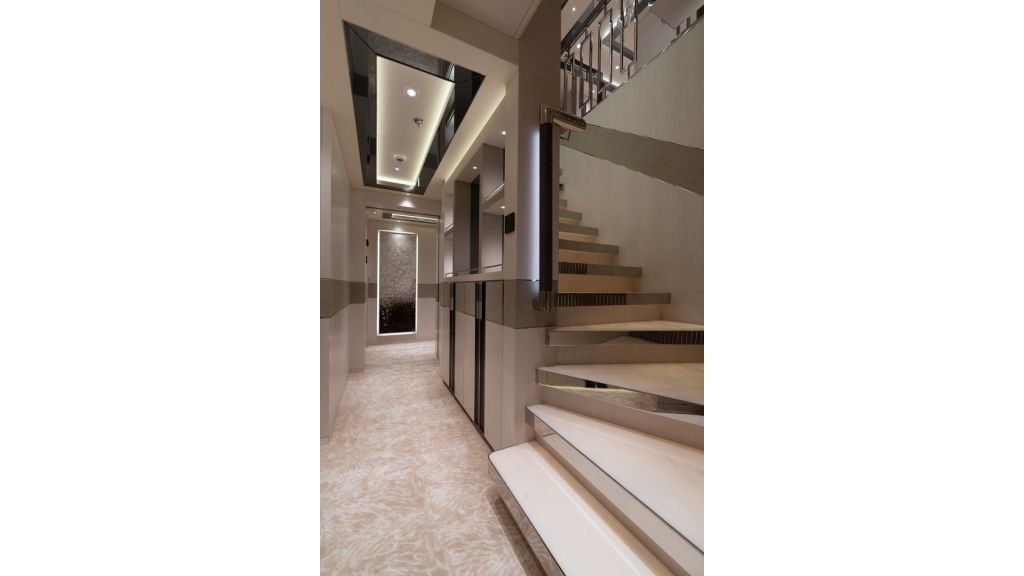

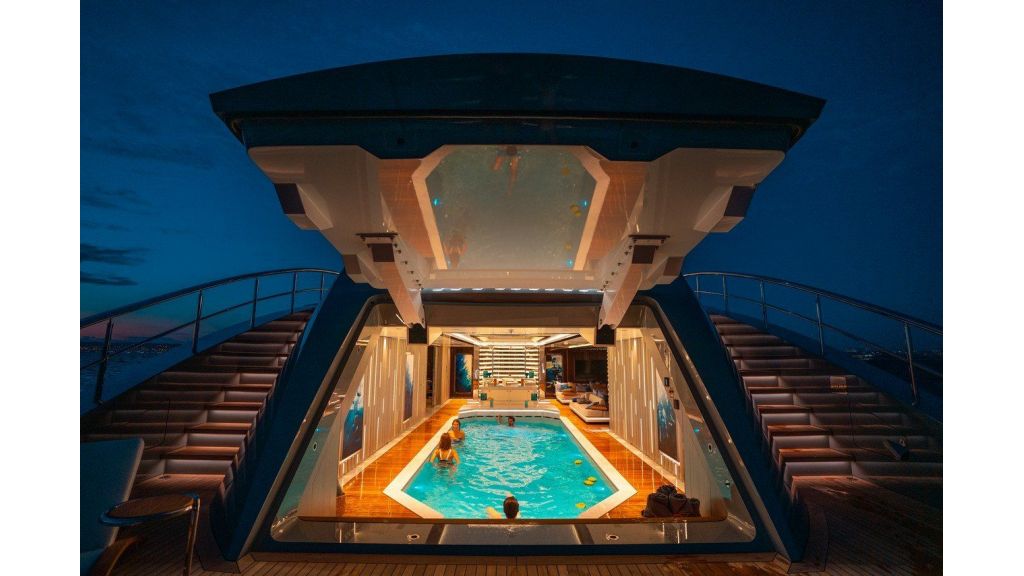

Accommodation and Layout

TATIANA accommodates up to 12 guests in 8 luxurious cabins and includes 4 crew cabins for professional onboard service. Her interior layout maximizes volume, natural light, and functional flow, making her ideal for both private ownership and high-end charter operations.

Currently Shipyard building

1x 74 meters (Which is available for sale immediately)

https://akasiayachting.com/74m-243ft-megayacht-in-construction